-

Place

Gela

-

Year

2009

-

Architectural Project

Mr. Fortunato Motta

-

Membrane Project

Maffeis Engineering

-

Area

2.000 mq

-

Textile

PTFE

-

Type

Archaeological areas - PTFE cover for archaeological site

-

Canobbio Textile Services

Membrane project support, production of membrane, fastening systems, tensioning systems, cables, installation.

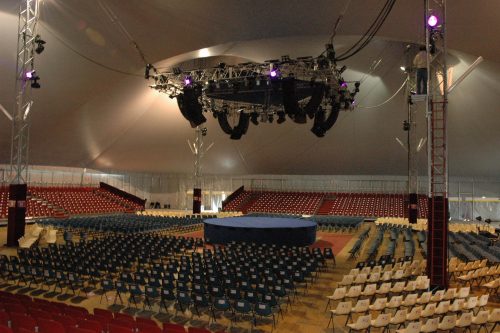

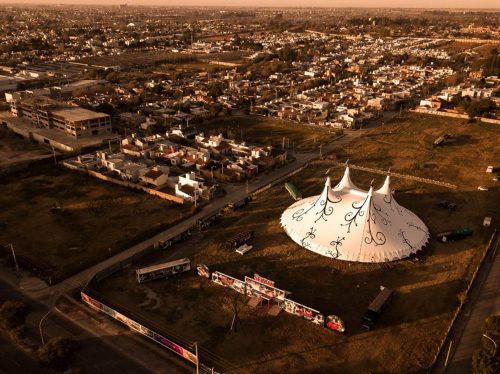

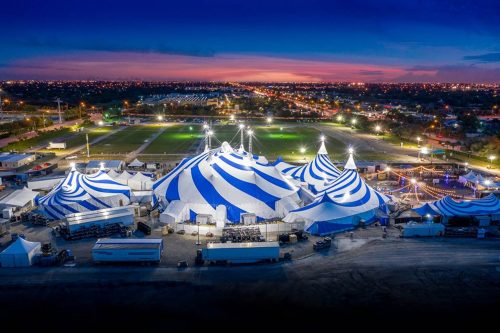

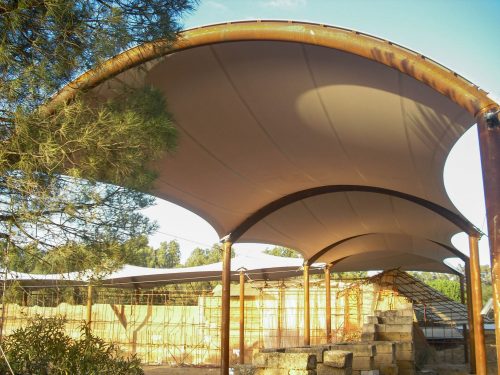

PTFE tensile structure Caposoprano - Gela

“Locally sourced technology and “know-how” are the elements that distinguish this two-thousand-square-meter structure, designed by Fortunato Motta of the University of Catania. This structure consists of a fibreglass PTFE cover designed by Studio Maffeis and supplied by Canobbio Textile Engineering to shelter the famous “Timoleontee Walls”, Ancient Greek fortifications in Gela that represent a very important archaeological evidence of the defensive system that surrounded the hill on which the ancient Greek city of Gela, founded by settlers from Rhodes and Crete in 689 BC and definitively destroyed in 282 BC stood. The PTFE tensile structure consists of a light modular cover, each saddle-shaped, entirely made of fiberglass and covered on the upper surface with Teflon, supported by several anti-seismic frames, positioned at about 15 metres from each other, made of 40 cm diameter tubular sections made of special alloy, totally resistant to corrosion by atmospheric agents, referred to as “cor-ten”, a steel four times stronger than conventional steel with carbon due to the presence of copper and chromium”.

Using our special heat bar welding technology, we – at Canobbio Textile – produced the Teflon coated fibreglass membrane, supplied the fastening and tensioning systems and coordinated the cover installation phase.