-

Place

Malta

-

Year

2016

-

Architectural Project

Mr. W. Hunziker and Mr. M. Kiefer

-

Membrane Project

Form TL, Germany

-

Area

4.820 mq

-

Textile

PTFE

-

Type

Archaeological areas - Cover for archaeological site

-

Canobbio Textile Services

Membrane project support, supply and production of membrane, fastening details, tensioning details, cables, installation.

Hagar Qim & Mnajdra Temples - Malta

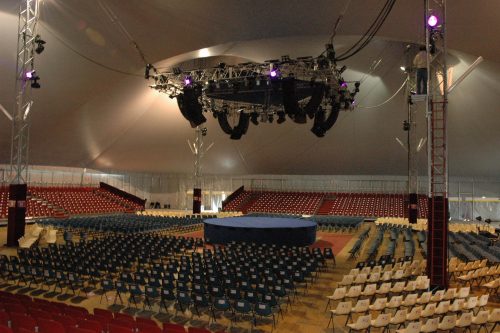

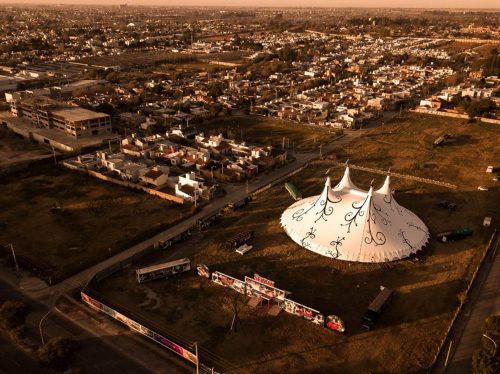

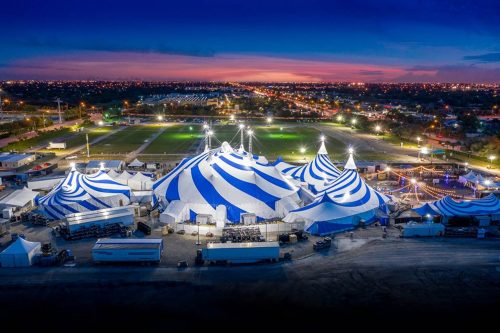

For Canobbio Textile the two tensile structures were without doubt the most complex projects due to some factors such as: the total exposure of the area to atmospheric agents, the extreme sensitiveness of the archaeological site and the resulting impossibility to operate within the area with lifting means.

“They were built between 3600 and 2500 BC and correspond to similar monuments in England, Ireland and Northern France. Astronomical alignments were first recognised at the Mnajdra Temple and later at the Hagar Qim temple too. Mnajdra preannounces the first day of the four seasons, solstice and equinoxes. As a matter of fact, it was rightfully named the “stone calendar”. It was opted to install textile covers on the two temples due to the fact that they offered the possibility to immediately and significantly delay the main causes of deterioration of the temples themselves, while allowing the continuation of research to reinforce the structures and restore elasticity to the elements. As a matter of fact, this type of cover allows the carry out low risk, fast and reversible works. Besides having considered the various views as well as equinoxes and the solstices, the shape of each cover – same case applying to the points of anchorage to the ground – were carefully studied and adapted to the topography of the respective sites. The cover membrane is made of fibreglass coated with white PTFE and the bearing structure is made of opaque grey steel. The membrane filters daylight, reducing it by about 10 – 15 % compared to natural light intensity. Therefore, this allows to visit and enjoy visiting the temple under natural light.”