-

Place

ÄÄNEKOSKI

-

Year

2021

-

Architectural Project

Canobbio Textile

-

Membrane Project

Canobbio Textile

-

Area

6.048 m²

-

Textile

TYPE E exterior - Special inner membrane

-

Type

Energy-P Advanced air-supported structure

-

Canobbio Textile Services

Design, processing and supply of cover membranes, supply of entrance/emergency doors, supply of utility tunnels, supply of light system supports, supply of L and U-shaped securing sections, Assembly technical support.

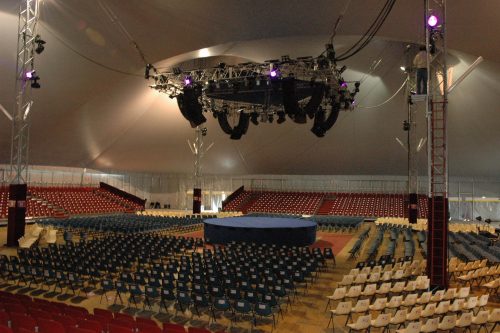

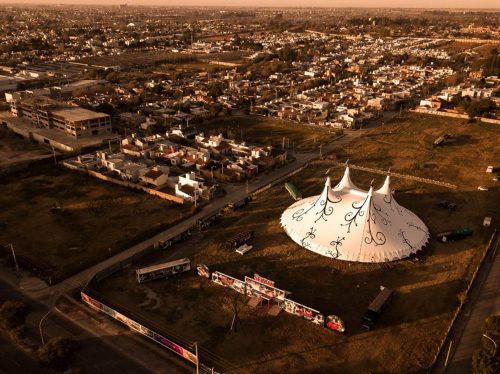

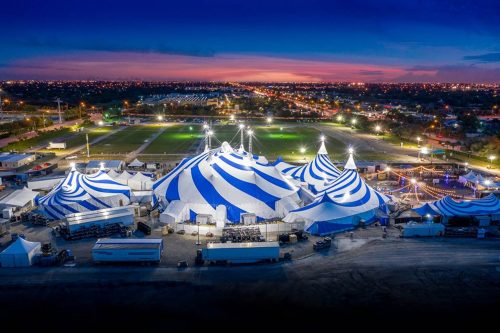

ENERGY-P ADVANCED Äänekoski

“The experience gained in designing and building large and advanced technology air-supported balloons, make the textile a valid solution for covering entire football fields. These projects where the energy efficiency and functionality of the structure are combined with architecture, are a fertile ground for interesting projects by using durable textiles and advanced engineering solutions”.

This is the case of the air-supported balloon built in conjunction with the PoVe consortium for the town of Äänekoski

in Finland, where we – as Canobbio Textile – built a cover measuring 100.30 m x 60.30 m wide to cover the winter playing field of the town’s football team.

The permanent air-supported balloon was made using the innovative ENERGY-P ADVANTAGE technology developed in recent years. It consists of: two fully detached membranes measuring 40 cm and connected to each other with a tested and patented system of stamps and cables. Comparing the three types (Single membrane, Double membrane and Energy) – considering the same climatic conditions – it is clear that the DM allows to save 11% compared with the SM while the Energy solution allows to save 20%. Another advantage that can be obtained, compared with the DM, lies in the elimination of the thermal bridge along the perimeter of the pneumatic cushions; avoiding condensation and eliminating dispersions on the perimeter (doors and ground joint) allows to save by more than 49% as a whole.

Besides the two fully detached membranes, an internal membrane was tested and used with a special treatment which has two functions. In winter, the membrane allows to preserve the heat of the cover, given that it has a lower dispersion and save energy significantly. In summer it reduces radiation and the resulting internal overheating.